Why continuity and consistency are key in freight management

We often get questions on how we reach double-digit savings (10%-30%) on freight costs while maintaining the desired quality. To answer this, imagine the following: have you ever tried walking to a destination, and deviating from your route or even changing your destination every 10% of the way? Or have you tried not starting to walk in the first place because you are waiting for an update of your navigation system? Doesn’t sound very effective, does it? Because it isn’t. In reaching your destination, every step adds to efficiency, not just the first ones or last ones. Yet, this is what we see happen very often when it comes to how shippers organize and manage freight. The key reason is lack of continuity and lack of consistency.

Consistency

Consistency

For shippers, in practice, transport is often a very day-by-day business. Sometimes procurement puts a dot on the horizon. But not much happens in checking whether the daily operations are moving efficiently towards that dot, and if daily operations are consistent with the plan.

Continuity

When looking at the shippers with which we have long term cooperations, there is no organization that hasn’t almost completely changed staff over the years, from the procurement to logistics team. In itself this is a natural process, but it often this lack of continuity leads to suboptimal situations. New team members are not aware of longer term strategy, or want to change it. Changing strategy should definitely always be an option, but changing it too frequently is counter-productive.

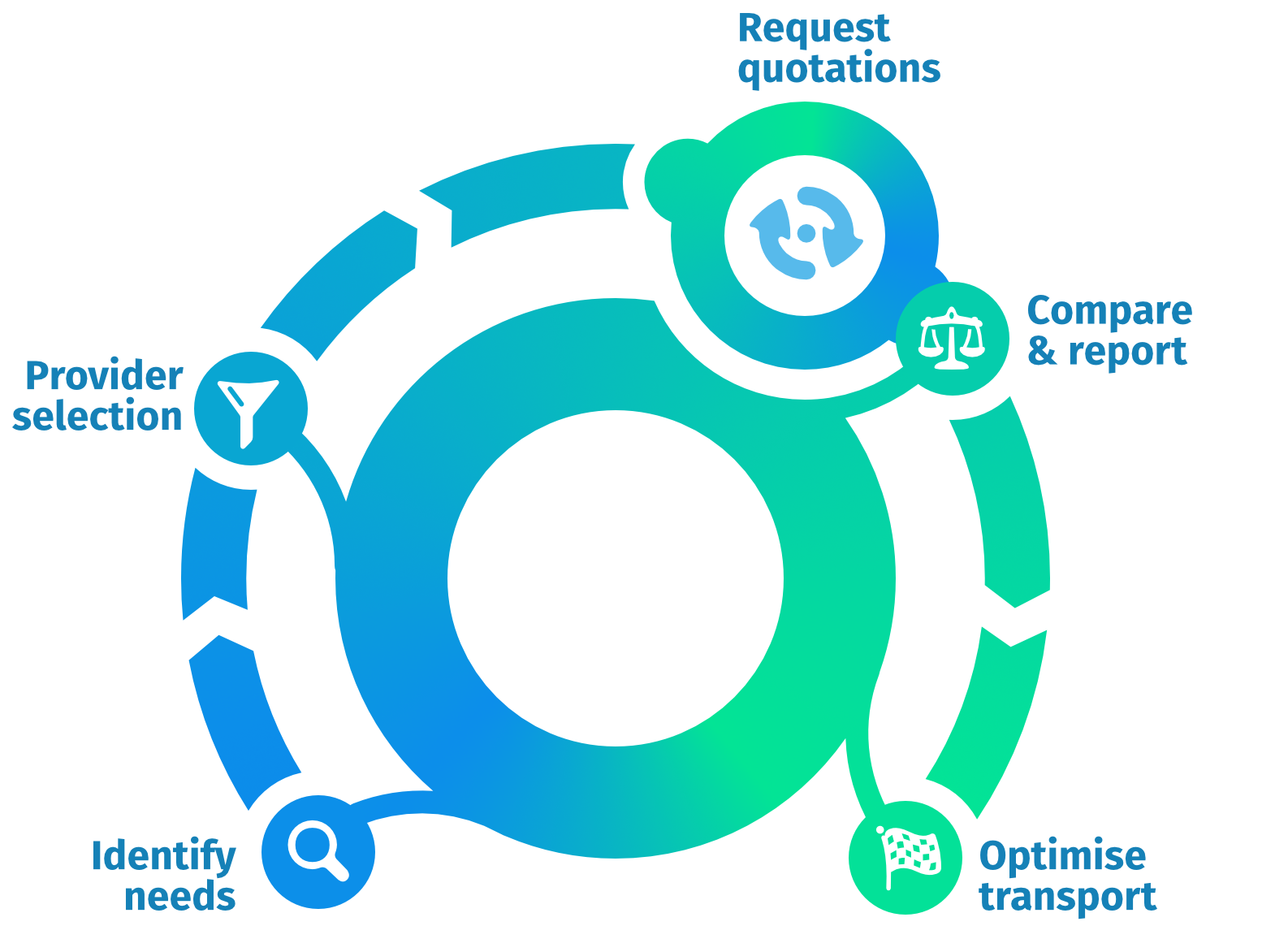

Step-by-step plan for control tower service

This is why, in addition to our procurement service and transport management application, we can also help safeguard continuity and consistency in reaching goals on freight spend, sustainability and service level. We advocate the following steps for companies AND ensure they are followed consistently if our clients use our control tower service.

- Define the longer-term strategy for transport as part of overall company strategy.

- Execute procurement while embedding the strategy in transport tender requirements in addition to daily operational needs.

- Translate the outcome of the procurement process to a transport plan.

- Manage the transport plan, ensuring you have near real time access to data in one single environment (TMS for shippers).

- In addition to daily management, implement a control tower that periodically safeguards the transport plan gets implemented or adapted when logistic service providers do not perform or when your own operation changes.

- Use control tower data to sharpen your strategy and feed procurement with accurate data and repeat the cycle.

Each of their above steps leads to percentages of cost reduction in your total freight spend. And there is no excuse for not starting today. There is no such thing as being ‘too busy’ or waiting for that fancy ERP, where we do not know exactly what it will bring for us, to be finally implemented. With our pragmatic approach, you can be up and running in days. If you do it right, consistent and continuous, you will save time and money and have returned on investment in a matter of months.

We will be happy to explore how this consistent and continuous process can be implemented in your organization.