Large multinationals, given their large freight budgets, can often justify having specialized freight buyers or managers on staff. With the right software applications, they are able to purchase and manage freight effectively. For companies where this is not the case, responsibility for freight procurement often falls under the logistics manager or generic buyers. This is precisely when we often see suboptimal procurement processes that lead to unnecessarily high freight costs. We describe some of the issues.

Time

For many companies, purchasing and managing freight is not a full-time job. Usually, a procurement project, also called a tender, comes up on the agenda every few years. It then becomes an additional task, and for the logistics/procurement manager, it can be a daunting task to fit it into their busy schedule. Certain phases of a procurement process require a lot of time, while in other phases, there is very little or nothing to do. The variability in time spent can therefore be a reason to hire an expert to handle the peaks. Note that they should be available based on flexible hours for the duration of the project (often several months), and clear agreements should be made about the time spent.

Process knowledge

Because purchasing freight occurs very sporadically, it is logical that little to no process knowledge and experience is developed. During the freight procurement process, many strategic decisions need to be made, which must then be translated into complete but concise tender documentation. Incorrect choices and inadequate or overly complete documentation have a direct impact on quality, price, and thus procurement results. In addition, the result may be that the received quotes are difficult to compare, which often leads to significant delays. A specialist knows exactly how things work and will ensure that the process runs quickly and effectively, without any surprises afterwards.

Market knowledge

As of 2021, the Netherlands had 14,805 companies with a license for professional road freight of goods. In the European Union, there are more than 600,000 (exact figures not known for 2021), all with different networks, services, materials, people, and rates. It is obviously impossible to know them all. But specialists who purchase freight daily see many logistics service providers, unlike “occasional” purchasers. Therefore, based on data and experiences from previous projects, specialists can select the most suitable parties that meet the requirements of a tender. This knowledge ensures an efficient process with a limited number of suitable providers. This saves time, ensures that all providers have a good chance, and often leads to the most competitive market price for the requested service.

Software

To purchase road freight, buyers need good software. It is necessary to be able to translate complex rate tables with different surcharges, load meter and volume keys, for a shipment profile, into costs. This allows the purchasing party to get a good idea of where which service provider(s) can be best used and what cost advantages the use of an increasing number of service providers has. In addition, the software should be able to generate accurate feedback that the participating service providers can use to refine their quotes in the next round of tenders. Often, purchasers use “standard” Excel fill-in templates to simplify the process without tools. Even various tender software packages work with a digital template. We explain why this is “killing” and almost always leads to higher costs here.

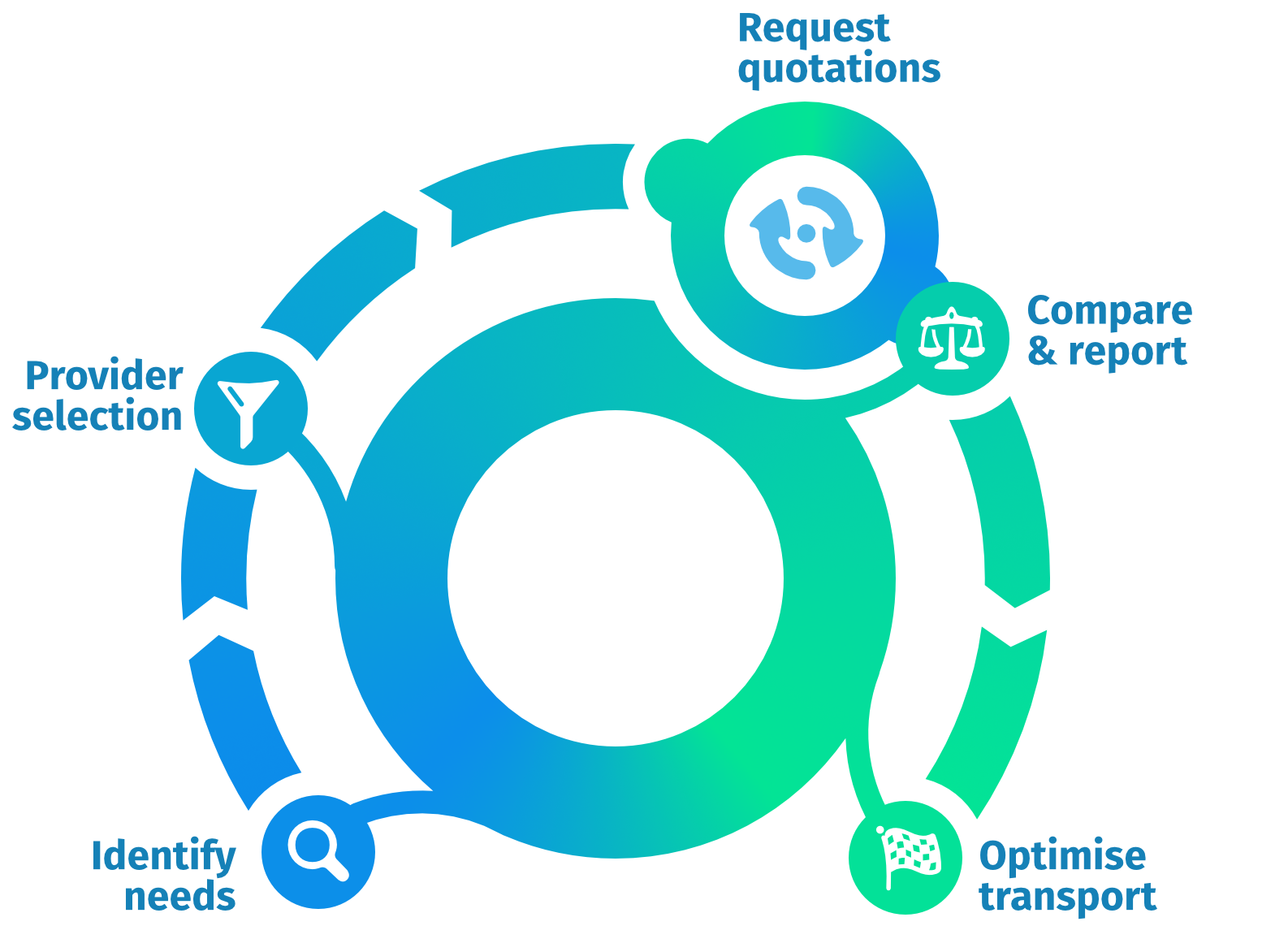

Summarized

To tender for road freight effectively, buyers therefore need sufficient time/capacity, process knowledge, market knowledge, and specific software. If any of these aspects are lacking, it may be wise to seek external support from an expert with the right software. If you are considering hiring an interim freight buyer or interim freight tender, …

Would you like to learn more or have a discussion about your procurement process? Please feel free to contact us.