We have compiled the top 10 tips to save on freight costs:

- Ensure you procure periodically

- Leverage the strengths of carriers

- Optimize packaging sizes & pallet layout

- Optimize order volumes

- Optimize delivery frequencies

- Analyze and reduce surcharges

- Find the ideal balance between contract rates and spot rates

- Use a different modality, larger or different trailer

- Automate the operational process with transport management software

- Take Control and become your own Control Tower

Got a quick question?

Call or email us directly. Our advisors are available to assist you.

Tel: +31 172 74 00 90

E-mail: info@transinnovate.com

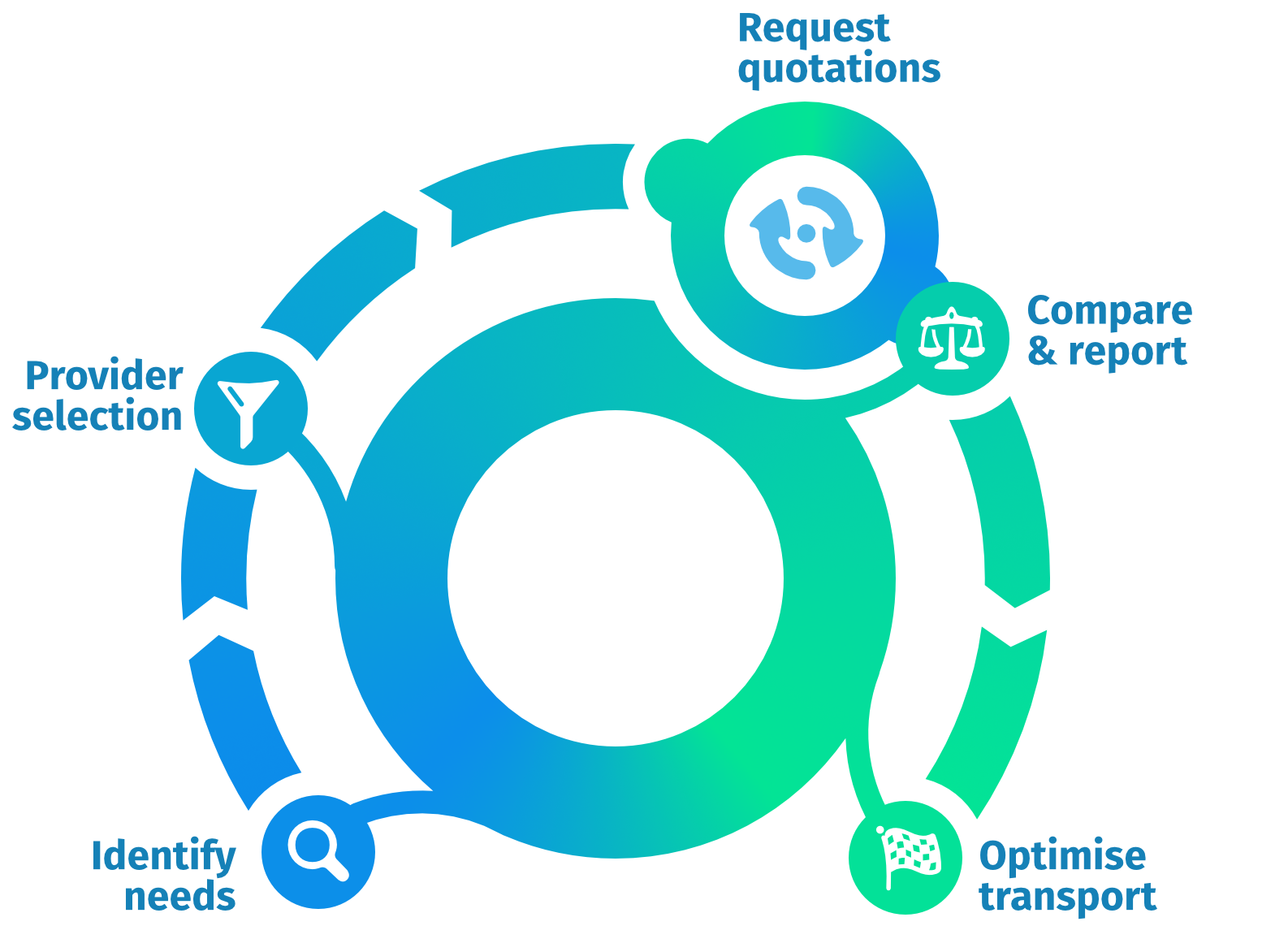

1. Ensure you procure freight periodically

Perhaps an obvious one, but effective purchasing is one of the most important aspects of saving on freight costs. It is crucial to have thorough knowledge of the (RFQ) process, the market, and the right software tools. If this is not the case, it may be better to outsource the procurement process, also known as tendering, to an expert. These three aspects are crucial for saving many extra percentages during a tender. Make sure to benchmark your rates periodically (advice: every 3 years). Want to learn more about the pitfalls of purchasing or interested in tips during the tender process? Feel free to check out our blogs or our tender service and gain inspiration on the subject of purchasing freight.

2. Leverage the strengths of carriers

We often see shippers not making optimal use of their carriers potential. What we mean by this is that shippers assign carriers, for example, by country or for the wrong shipments. A distribution on a country level may be easier to organize operationally, but it is often far from optimal in terms of service and freight costs. There are many specialists in the market, groupage, LTL, FTL, modality, country, region, etc. Finding the ideal combination and using it properly will lead to lower transportation costs and often better service/quality. We once wrote a nice article about this.

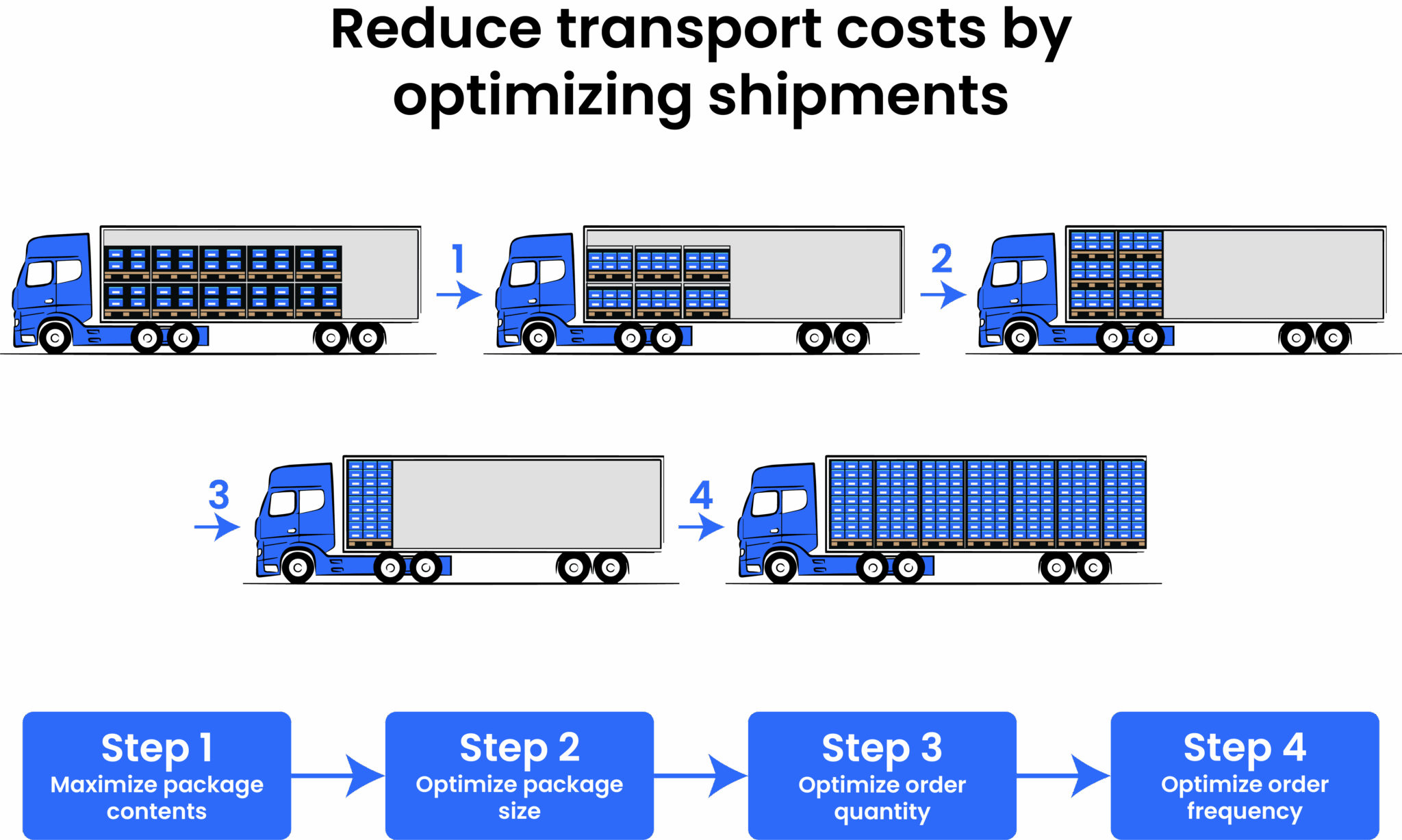

3. Optimize packaging sizes & pallet layout

Freight is always charged based on loading meters, volume, and weight. For this reason, it is wise to systematically examine what and how exactly is being shipped. Try to avoid shipping “air” as much as possible. Sometimes simple actions can be taken in the warehouse to package or stack items more efficiently. However, it is also sometimes wise to talk to product development before products are actually introduced. What may seem interesting from a marketing perspective can sometimes be a huge transportation cost.

4. Optimize order volumes

Ensure that order volumes are aligned with the shipping unit in which or with which they are shipped. We will explain this with a simple example: a logistics service provider has agreed to a price per pallet, assuming that the pallets are fully stacked. 27 boxes of a certain product fit on a pallet. Then it is wise to keep the order volume at 27 units. For 26 or fewer boxes, we pay the same cost as for 27 boxes, and for 28 or more boxes, we even pay double the cost because an extra pallet must be shipped. Look closely at order volumes, packaging sizes, and price agreements; there are likely opportunities to reduce transportation costs.

5. Optimize delivery frequencies

Shippers will need to regularly analyze their shipping profile. For example, how often are shipments made to the same address within a certain time frame? Or perhaps there are shipments that can be better scheduled in a milk-run.

Combining shipments will not only reduce handling in the warehouse, but will also result in lower transportation costs due to the rate scales often used by service providers. Sometimes, the sales department will need to be consulted to educate customers or create some flexibility. Customers will be more willing to adjust their ordering behavior if savings can be shared with them. Use the sustainability aspect where necessary to convince customers.

Want to save even more on transportation costs? Request the free demo of our Transport Management Software!

- 24/7 support by transport experts

- All carriers in one overview

- Directly save costs & time

- 90-day free trial

- Request a free demo

6. Analyze and reduce surcharges

There are two types of surcharges. Those that are charged because certain (service) choices are made when sending the transport order. Think of an urgent delivery, delivery at a certain time, delivery with a truck with a ramp, delivery on a floor, etc. In addition, there are surcharges that are charged afterwards and unexpectedly. For example, because no one was available at the time of delivery and a second delivery must be scheduled, waiting times, incorrect freight, problems with goods, etc. Ensure insight and control over all surcharges that are charged. Ideal is registration and approval during the operational process, so that invoice control becomes easy. Analyze the surcharges afterwards and discuss with the relevant stakeholders to reduce them. If you do not have insight and control over surcharges, read on at point 10.

7. Find the ideal balance between contract rates and spot rates

Transport orders are forwarded either from contract rates (and price agreements) or based on a received spot rate. Contract rates provide certainty in terms of price fluctuations as well as in the case of necessary service and reliability. The costs of spot rates can sometimes be much lower, but availability is not guaranteed. After all, a large percentage of all trucks are empty and service providers sometimes prefer to transport something rather than nothing. It is important for companies to find the ideal mix between contract and spot rates that suits their strategy. With our transport management software, shippers can easily send transport orders from contracts or request spot rates when desired.

8. Use a different modality, larger or different trailer

Investigate the possibilities for transporting goods differently. This includes transportation by train, barge (inland waterways), by sea, in containers instead of trucks, or with larger trucks such as LZVs, mega or jumbo trailers. In all cases, this will not only result in cost savings but also have benefits in terms of transport sustainability.

9. Automate the operational process with transport management software

Shipping often involves a lot of manual work for shippers, including sending and keeping transport orders up-to-date and managing surcharges. When this is still done via emails or logistics service provider portals, mistakes are made too often. Even ERP systems are often too limited to perform these tasks well. In addition to the fact that managing the order flow and surcharges involves a lot of manual work and therefore costly time, there is sometimes also miscommunication about loading and unloading data. This can result in logistics service providers showing up too early or too late to load or unload, which can result in additional (incorrect freight, urgent extra delivery) surcharges. Solve this easily by using a TMS. Automate the operational process, gain control over orders by managing order statuses, and reduce transportation costs by preventing misunderstandings.

10. Take Control and become your own Control Tower

The topic of Control Towers is very trendy. We let a 3PL or 4PL specialist organize all of our transports! We expect the provider of this service to achieve all 9 points mentioned above, we expect complete transparency in everything that is done, and in doing so we easily lower our transport costs. It’s no secret that for such structures, Control Tower providers often charge gigantic amounts and transparency is often lacking…. An easy way to lower transport costs is to act as your own Control Tower. What do you need? A suitable TMS that allows shippers to easily analyze and optimize themselves. If you prefer to outsource the most complex aspects of optimization, we call that: transport management services. Last but not least, make sure that your Control Tower partner is completely transparent. Make sure beforehand that your partner does not receive commissions from carriers. If your Control Tower partner has their own trucks, make clear agreements. Make sure they do not use them suboptimal and therefore for their own benefit.

If you want to know more about how we can help you lower your freight costs, feel free to contact us.