Mapping your logistics process leads to lower freight costs

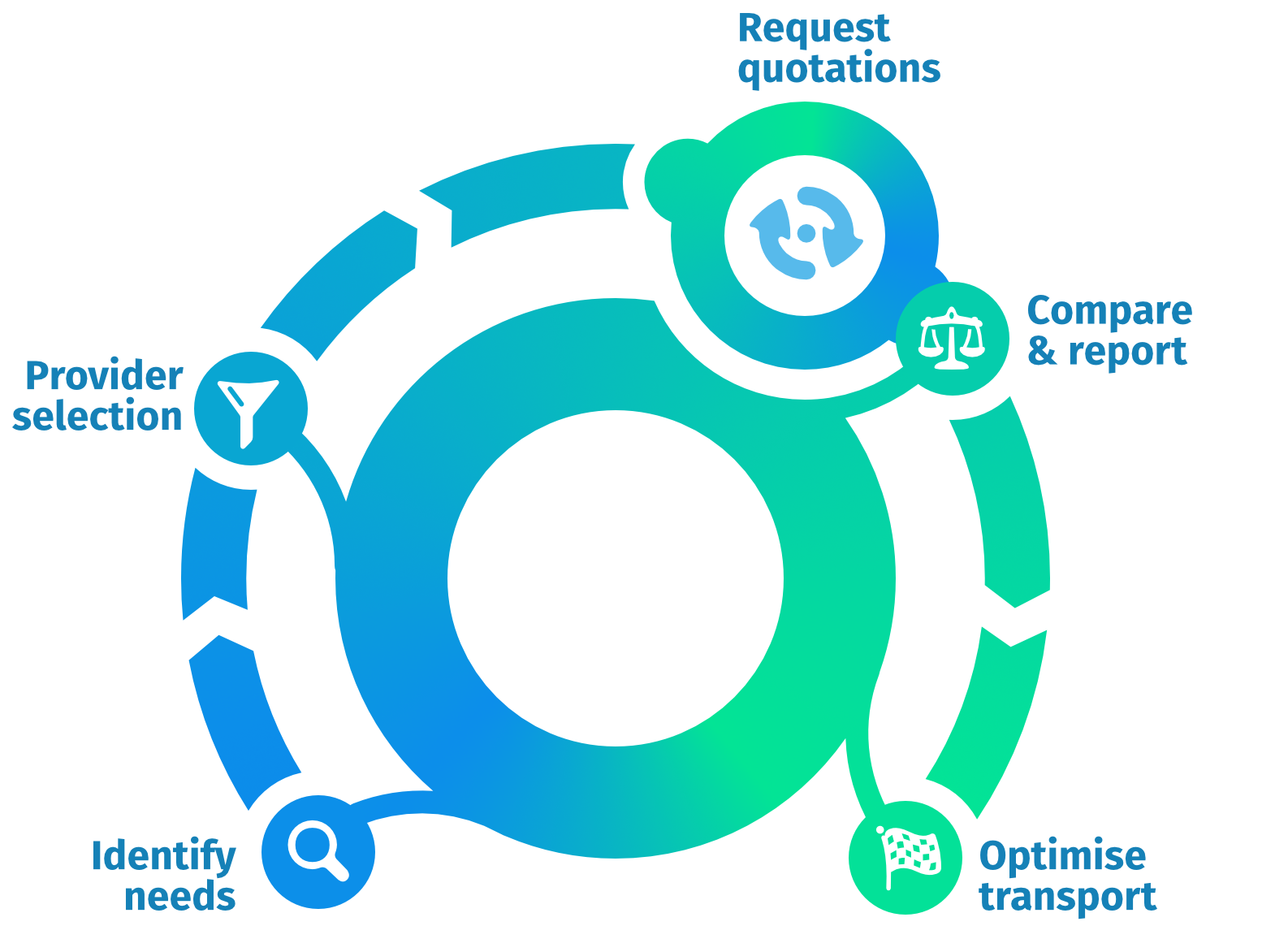

When shippers want to reduce transportation costs, it is essential to conduct a thorough analysis of the logistics process. Mapping the logistics process accurately, forms the basis for reducing transportation costs. Without a good understanding of the process, there is a risk that companies will solely focus on procurement. They might think that by purchasing smarter, better, more effectively, or differently, they will reduce their transportation costs. However, through a comprehensive analysis of the logistics process, companies can find various other ways and often more impactful ways to lower transportation costs. Below are some examples:

Footprint analysis

By mapping the process accurately, you can identify inefficiencies that may impact transportation costs. For example, unnecessary transport movements due to products being produced or stored in the wrong location.

Shipment consolidation

By creating a detailed overview of shipments, you can identify opportunities. This includes customers who frequently place consecutive (LTL – less than truckload) orders or using Jumbo or Megatrailers for FTL (full truckload) shipments. The inherent volume bonus in rate tables implies that improving load utilization leads to cost savings and efficiency improvements in the operational process.

Inventory management

Mapping the logistics process also provides insight and control over inventory management and storage locations. External warehouses are often used to store excess inventory, which incurs additional transportation costs.

Transportation management

Understanding the logistics process clarifies how transportation management activities are carried out. Are companies only collaborating with fixed partners? Are shipments outsourced on the spot market? Are the right parties selected for shipments? Are there other available transport modalities? Properly managing transportation directly reduces transportation costs. This is possible with TMS software.

Inbound logistics

Inbound logistics

Gaining insight into the process may reveal ill-considered decisions made by the procurement department regarding the Incoterms used when purchasing raw materials. This could result in expensive delivery of raw materials.

Bottlenecks in production process

frequent delays in production causes the need for (costly) express transport services to still deliver on time or at least minimize delays. Depending on the root causes, bottlenecks can be solved in the actual production process, or by accounting for a buffer in agreed delivery times after order.

Methodes for your logistic process

In addition to these points, there are numerous other aspects of the logistics process that can influence transportation costs, such as transport planning, cross-docking, order handling, carrier management, invoice control, customer-specific surcharges, and more. Clearly, mapping the logistics process accurately can lead to cost reduction. Now the question arises: how can you effectively map the process?

There are several methods you can use to map logistics processes for shippers. Here are some commonly used methods:

Process Mapping

This visual method maps the process step by step. Symbols and diagrams are used to illustrate the relationships between process steps, decision points, involved parties, and information flows. A popular form of process mapping is the use of flowcharts.

Value Stream Mapping

This method focuses on identifying waste and improving efficiency in a process. It maps the complete flow of activities from start to end result. It also considers information flows, waiting times, and potential bottlenecks in the process.

Swimlane Diagrams

This method is often used when multiple parties are involved in a process. The diagram divides the process into horizontal “lanes” (swimlanes) responsible for specific parties. This clarifies which tasks are performed by which party and how they collaborate.

Interviews and observations

Conducting interviews with employees and other stakeholders involved in the process, and performing visual on-site observations, can gather valuable insights. Having conversations and observing the process firsthand often provide different insights than discussing the process solely around a meeting table.

Brainstorming sessions

Organizing brainstorming sessions with relevant stakeholders can help gather different perspectives and ideas about a process. Jointly thinking about the process can bring forth improvement opportunities and identify pain points.

Using a combination of these methods to map the logistics process effectively is logically the most efficient approach. If you need assistance, our holistic approach can help businesses minimize freight costs.