The ideal way to optimise your logistics

Logistics optimisation is essential to remain competitive in the modern world. It is not just about moving goods from point A to point B, but about finding the most efficient and cost-effective way to do so.

Logistics optimisation is essential to remain competitive in the modern world. It is not just about moving goods from point A to point B, but about finding the most efficient and cost-effective way to do so.

When optimising logistics, particularly transportation, minimizing costs, improving delivery speed and reliability, ensuring sustainability, and continuous improvement are all crucial. Technology and software play a more important role than ever before.

But where do you start when it comes to optimising logistics? It all begins with mapping out the logistics process. Read more about it in our blog post: Mapping the Logistics Process. By identifying and quantifying bottlenecks and opportunities using a specific methodology, companies can prioritize their efforts.

In many cases, logistics optimisation revolves around transportation and transport costs. At Transinnovate, we have years of experience with optimising transportation, costs, service, and sustainability for shippers. We recommend to put the following three pillars in place in your organisation.

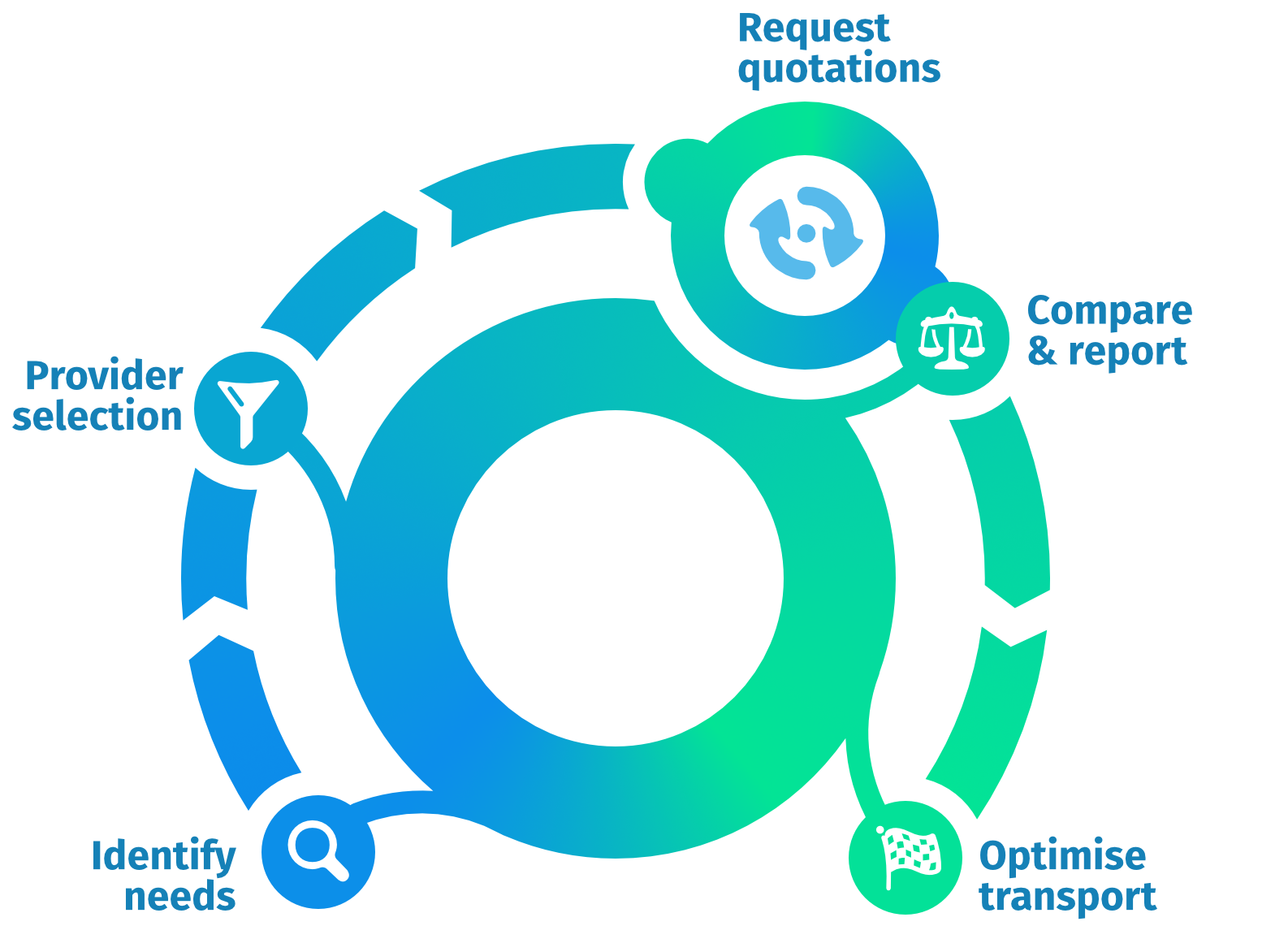

1. Data-driven Freight Procurement

Comparing rate tables, or even worse, prescribing rate tables in fixed formats is the biggest pitfall in freight procurement.

Smart procurement aims at finding the best set of carriers for your specific shipment profile, for the service level you need. Comparisons should be based on translating your shipment profile to costs with the offered freight rates. We are often surprised how many shippers do not have accurate insight into their shipment profile.

The next step is scenario analysis to find the optimum mix of logistics service providers (LSPs), also accounting for service level and sustainability.

Cost calculations and scenario analysis do require dedicated and smart software solutions. The result is a transport plan with ideal partners that perfectly aligns with your company’s strategy. Learn more here.

2. Transport Management System (TMS)

Once the plan is ready, you need to make sure it gets implemented properly and efficiently, also accounting for daily challenges and changes. Modern TMS solutions offer the ability to (nearly) fully automate freight operations.

Once the plan is ready, you need to make sure it gets implemented properly and efficiently, also accounting for daily challenges and changes. Modern TMS solutions offer the ability to (nearly) fully automate freight operations.

Think about streamlining freight activities including:

- smart load allocation

- placing of orders

- requesting spot rates

- scheduling loading docks

- managing transport documentation

- real-time shipment tracking

- and more…

A misconception is also that TMS are big complex systems that are costly and require long implementation times. The most modern TMS systems use the latest SaaS technology and a modular approach. This enables rapid implementation (days to weeks) and customizing at affordable costs for Small and Medium Enterprises up to multinationals. Find more information here.

3. Control Tower

Once you have a plan (from procurement) and means to implement it on a daily basis, this is not the end of the story. In order to capitalise on opportunities for improvement in cost, service and sustainability. This requires a structures and periodic analysis by a Control Tower function that takes a step back from daily operations.

Although a TMS provides the data to feed a Control Tower function, we often see that companies do not have the bandwidth, time or expertise to implement a control tower properly. If this is the case, you can contemplate on outsourcing this. If you outsource a control tower function, then make sure the party running this for you is independent and doesn’t have agreements with carriers that provide a hidden agenda.

A control tower, when executed properly provides a step by step plan for continuous improvement and feeds the next procurement cycle with proper data and real operational (service) experience with the various logistics partners. Discover more here.

4. Extra tips to optimize your logistics

In addition to the above pillats, we have several more tips from our experience that can help businesses optimise their logistics and reduce freight costs in many other ways. By thoroughly analysing a shipment profile, you can easily lower costs by focusing on the following areas:

- Load factor simulations: Can you serve the same customers less frequently with bigger shipments?

- Routes: Can you create smart combinations with multi-drop shipments?

- Modality & Trailers: Can you load more or perhaps in a more sustainable modality?

- Inbound: Can you improve by picking up products ourselves instead of relying on deliveries?

- Combinations: Can you consolidate shipments?

- Return shipments: Can you load backhauls in the vicinity of your destinations, or can you find carriers for who your freight is their return freight?

- Surcharges: Where are you paying surcharges, and are they always really required ?

- Invoice control: Is everything accurate? Are you being billed correctly?

To optimise logistics effectively, a holistic approach, time, and expertise are required. Do you want to brainstorm with us about your opportunities? At Transinnovate, we understand the importance of logistics optimisation and offer tailor-made solutions for businesses of various sizes.

Whether it’s minimising transport costs, automating freight operations, or providing a Control Tower service, we have the expertise and technology to support companies in their pursuit of efficient and cost-effective logistics.

Feel free to contact us if you would like to explore the possibilities for optimizing logistics for your company.